Table Of Content

Air duct sizing is a critical aspect of HVAC (Heating, Ventilation, and Air Conditioning) system design. It is essential for ensuring efficient airflow and optimizing energy consumption. This tutorial covers the fundamental formula used in air duct sizing, its creators, real-world applications, key contributors to the field, and some fascinating insights about its impact. The concepts behind air duct sizing are grounded in the field of physics, particularly fluid mechanics and thermodynamics.

Calculate the CFM for Each Room

Yes, different shapes have varying cross-sectional areas, which affects the velocity for a given air flow rate. Additionally, proper duct velocity ensures adequate air circulation while minimising noise, pressure drop, and energy consumption. Higher air velocity correlates with increased friction losses and energy consumption. The three branches within the main duct now receive equal air flow making a significant improvement to the design.

Figure Square Footage of Spaces

Three Steps to Avoid an Inverter Implosion Epidemic - Contracting Business

Three Steps to Avoid an Inverter Implosion Epidemic.

Posted: Tue, 18 Jul 2023 07:00:00 GMT [source]

For instance, if your HVAC unit has a height of 250mm (10″), your main duct should also be 250mm (10″). Hence, air can flow from one side of the room to the other side of the room instead of short cycling itself which can lead to all sorts of cooling problems. As a reminder, you need to identify the size and type of the grille/diffuser before this step. Otherwise, you don’t know how many numbers of grille/diffuser you need for each room.

Basic Ductwork Guide: How to Design Your Duct System

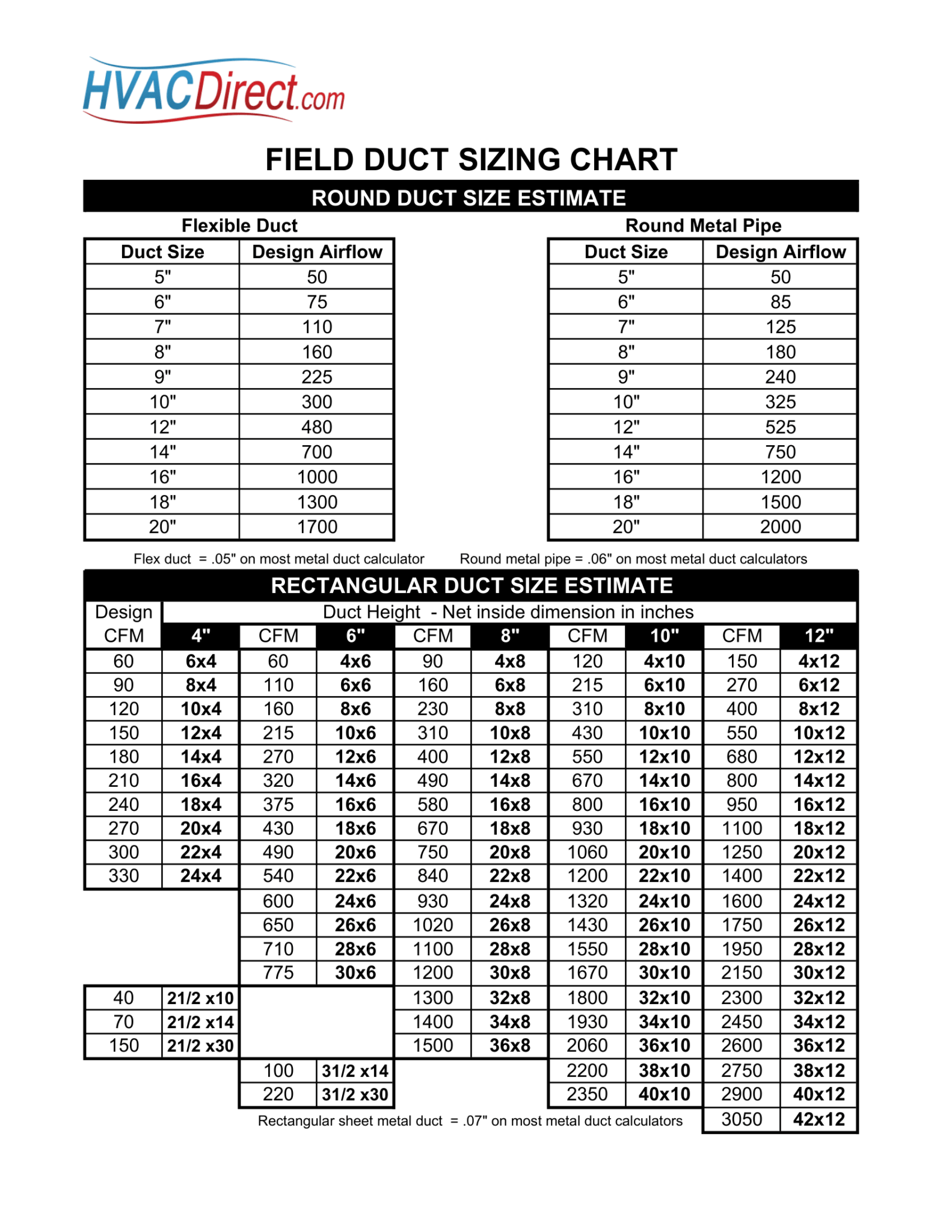

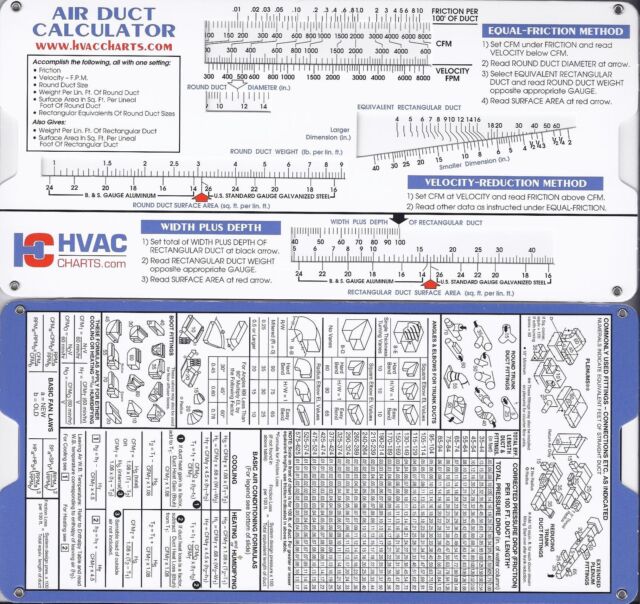

Users can input air velocity, friction factor, or duct dimensions to obtain the required duct size. Mechanical engineers, HVAC designers, contractors, and technicians can all benefit from this tool. It simplifies the complex process of duct sizing, allowing professionals to optimize airflow, ensure efficient performance, and comply with industry standards and regulations. Friction rate (FR) helps you decide the diameter and shape of ductwork you can use without negatively impacting optimal air flow. It’s calculated by using the available static pressure (ASP) divided by total effective length (TEL) and multiplied by 100 to show how much pressure drop the system can accommodate per 100 feet of effective length. You want a higher friction rate, because it means you can use smaller, more restrictive ductwork than on an HVAC project designed with a lower friction rate, which requires larger ducts.

HVAC Duct Design Calculator (Metric)

Friction in a system means the fan needs to work harder and this results in higher operating costs. Always use round duct where possible although in many cases rectangular duct needs to be used as space is limited. Keep in mind that you need to maintain a certain duct height regardless of the airflow. If you read my post on supply air diffuser sizing, you’ll understand why. Then, branch out the duct and extend it until it is close to the respective supply air diffuser. After I went through the diffuser selection process, I decided to use 2-slot 1200mm (48″) linear diffusers with a neck size of 150mm (6″) for both the supply air and the return air.

Here you can see both of the values we calculated fall between vales listed in the table so we need to perform a bilinear interpolation. To save time we’ll just use an online calculator to find that, link here (watch the video to learn how to perform a bilinear interpolation). The larger perimeter also means more air will come into contact wit the material and this adds friction to the system.

Duct Sizing - the Equal Friction Method

To calculate the area of a rectangular or square room, simply multiply the length and width of the room. You can also refer to a building’s blueprint, zoning drawings on file with the local planning office, or a recent real estate listing for the space, if available. Ductwork sizing is very important to indoor comfort and to the durability, performance and efficiency of the HVAC equipment – as important as sizing the equipment. Since ductwork is expensive and should last years, sizing it right is essential. Next we need to find the index run which is the run with the largest pressure drop. It’s usually the longest run but could also be the run with the most fittings.

The extreme high cooling capacity thermoelectric cooler optimal design for kilowatts scale thermoelectric air ... - ScienceDirect.com

The extreme high cooling capacity thermoelectric cooler optimal design for kilowatts scale thermoelectric air ....

Posted: Fri, 01 Dec 2023 08:00:00 GMT [source]

Can Round Flexible Duct Be Used for HVAC Return Air?

We take the chart and scroll up from the bottom left until we hit the volume flow rate of 0.79m3/s. Then we locate where the velocity line is of 5m/s and we draw a line across until we hit that. Then to find the pressure drop we draw a vertical line down from this intersection. As we’re using the equal pressure drop method we can use this pressure drop for all the duct lengths so fill those in too. Then we scroll up again and align our intersection with the upward diagonal lines to see this requires a duct with a diameter of 0.45m so we add that into the table also. In real-life, air duct sizing is crucial in designing efficient HVAC systems for residential, commercial, and industrial buildings.

On this page you can estimate the size of the ducts for the correct functioning of the ventilation system. The tool helps to calculate the cross-sectional area of the ducts according to the values of air exchange and air velocity of the air flow. Please note that the recommended velocity for residential areas is 3-5 m/s (but no more than 10 m/s). The required parameters for the calculation can be seen on the notation below.

This is also called the Maximum Friction Loss Rate – it measures how much air flow loss is caused by friction within the ductwork. You have two or three options for rectangular ducts that give you the same or nearly the same square footage per duct. It’s important to use accurate measurements and reliable calculation methods to avoid errors that could lead to inefficient system performance or discomfort for building occupants.

With the doors closed, the amount of airflow supplied to a room is limited by the amount that will exit from the room. An over pressurized room will expel conditioned air to the outside, attic, or crawlspace. I have to use return air ducts because I use one HVAC unit for the entire home and thus, there are multiple rooms to serve. Otherwise, you need return air ducts and it is advisable to have a return air grille in each room. To understand why, see my post Does Every Bedroom Need a Cold Air Return Vent & Duct?. Generally, return air grilles should not be placed too close to supply air diffusers.

A calculating web form for use with the Manual D procedure to determine the friction rate for sizing a residential duct system. A calculator that troubleshoots refrigerant and air flow issues of an air conditioner. Select the systems configuration and enter the operating temperatures and pressures.

For that we use the formula Co multiplied by rho multiplied by v squared divided by 2 where co is our coefficient, rho is the density of the air and v is the velocity. Most ducted air conditioners with BTU of cooling capacity have an external static pressure rating of 0.2 in.WG to 0.4 in.WG. Remember I mentioned earlier, all the diffuser neck size is 150mm (6″) and thus, all the flexible duct size is also 150mm (6″). In addition, I included a volume control damper (VCD) at the first few duct branches to better control the airflow.

Identify insulation needs and enhance thermal performance by accurately calculating the heat loss of a building, room by room. Choose from a range of international standards, add fixtures, and automatically receive the peak flow rate calculation. Calculate friction losses through a pipe quickly and easily, eliminating the need to perform complex mathematical calculations manually. We can calculate how much pressure drop each damper needs to provide simply by subtracting the loss of the run from the index run. We find it easily by adding up all the pressure losses from the start to the exit of each branch . Now if we look at the comparison for the two designs we have a standard design on the left and a more efficient design on the right which has been optimised using simscale.

Follow the same procedure as the supply air duct to design the return air duct. You need to install a return air plenum box behind your HVAC unit to accommodate return duct connections. This measurement indicates the air velocity or flow needed to accurately heat or cool a room. Since the size of your ductwork can increase or lower this measurement, you’ll have to find the necessary CFM for each room before you can get the right duct size for each space. Our air duct velocity calculator utilises precise engineering calculations to deliver accurate velocity values.

Ductwork is the network of pipes, commonly called duct, that connects your HVAC unit to the vents in your rooms. It is responsible for distributing the conditioned air evenly and efficiently throughout your home, while also removing stale air and contaminants. A well-designed duct system can improve your HVAC performance, efficiency, comfort, and air quality. In this guide, we will show you how to design your duct system step by step. We then need to calculate the dynamic loss caused by the bend changing the direction of flow.

No comments:

Post a Comment